Raising Lenthalls Dam with Crestgates

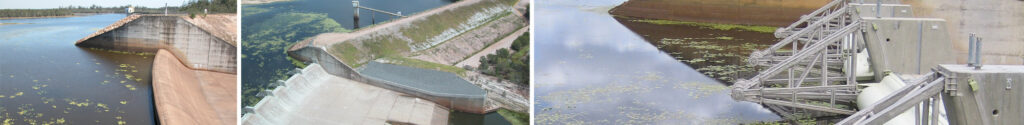

Wide Bay Water Corporation (WBWC) decided the most efficient and environmentally friendly system to raise Lenthalls involved installing a Crestgate system, never used in Australia before.

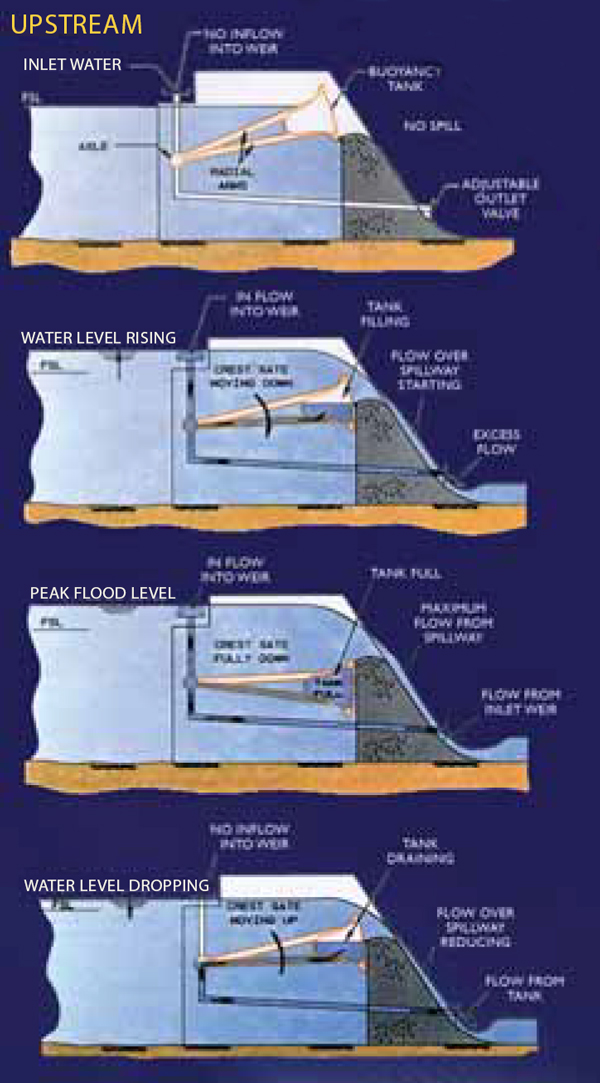

The gates go underneath the water and are raised from below, rather than closing from above. There are five gates across the spillway with concrete piers between each. This provides an option to only open some gates at some times, and to have greater control over environmental flows.

In times of flood, when the water reaches the top of the dam, the gates automatically submerge allowing the excess water to go over the spillway.

The cost of this gate system is about the same as building another concrete spillway structure, but offers much more control. It’s also less expensive than a number of other gate systems we investigated.

Lenthalls Dam Crestgates were completed in 2007.

Benefits:

- Firstly it pushes a lot of water through at once, flushing the waterways as if there wasn’t a dam.

- Secondly, it enables WBWC to quickly restore the dam to its proper level through increased discharge capacity.

- Thirdly, it also means that logs and other debris washed through in floods don’t get stuck in the gates, they simply wash right over. From a maintenance perspective, this is a great benefit.

- The cost of this gate system is about the same as building another concrete spillway structure, but offers much more control.

- Wongi Waterholes are protected by bundwalls and a system to pump out excess rainfall.

- The Crestgates raised the capacity of Lenthalls Dam from 17,800 Megalitres to 29,500 Megalitres.

Project cost $15,350,000

My role with the project

Raising Lenthalls Dam was a major project for WBWC and it was my role to manage marketing and communications for the project.

This included commissioning a scale model for the project, which actually uncovered a major fault - the engineering plans had been based on the original Crestgates in South Africa on a straight wall. Lenthalls Dam is actually curved. Manufacture had already commenced however I was able to demonstrate the fault in the design, WBWC recalibrated the specifications and the project could safely proceed.

I also made regular visits to the site to photograph the project progress. This included at ground level, by boat on the water, as well as aerial photography with many helicopter photo sessions over the years.